The Advantages of Plastic Molding for Electrical Components

In the world of Metal Fabricators, plastic molding for electrical components has become a crucial process that ensures the efficient production of high-quality parts. This advanced technique offers numerous advantages that can greatly benefit businesses in various industries.

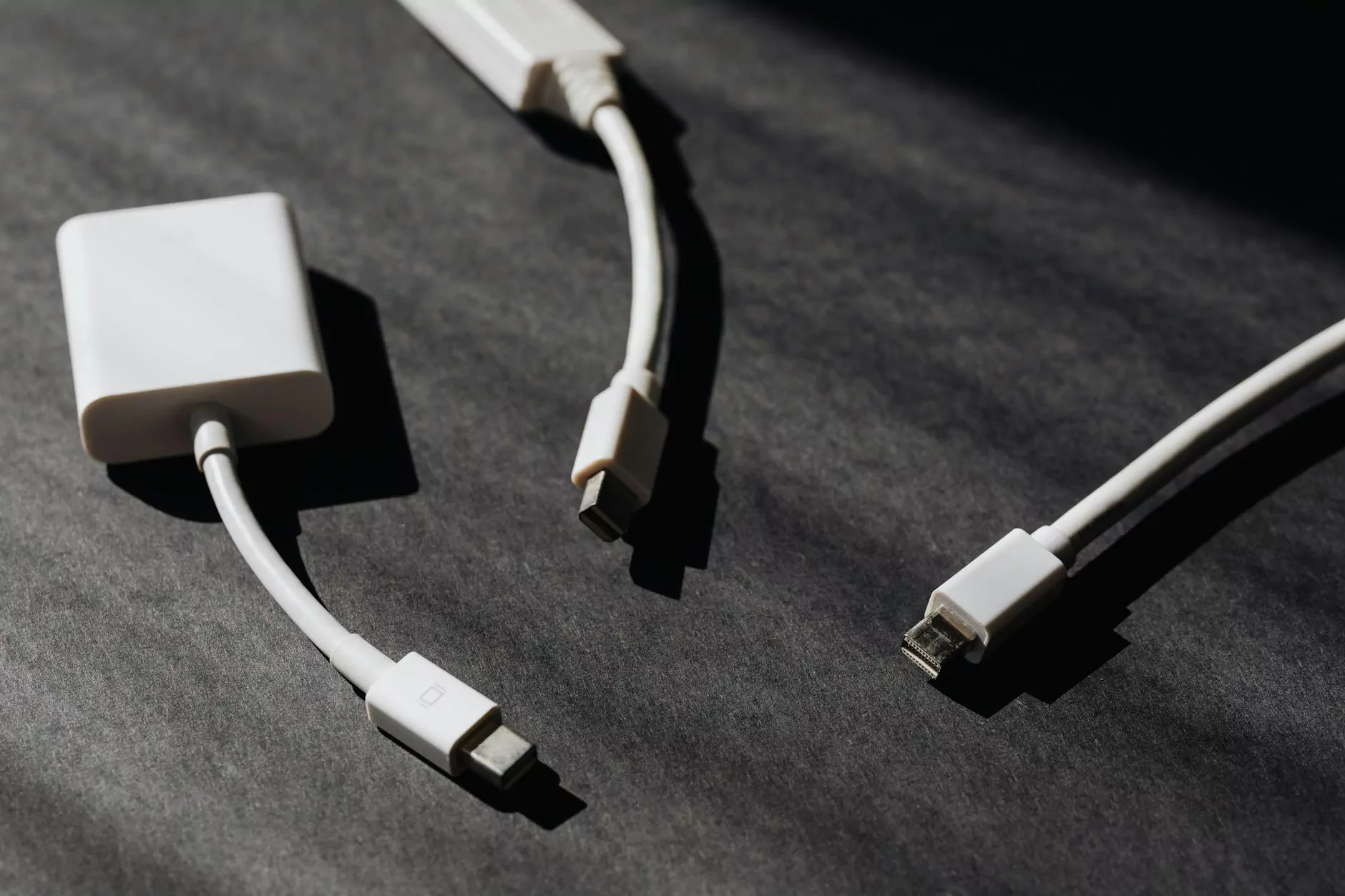

Understanding Plastic Molding for Electrical Components

Plastic molding for electrical components involves the use of specialized techniques and equipment to create precise and durable parts used in electrical applications. This process allows for the mass production of components that are vital in various electrical systems and devices.

The Benefits of Plastic Molding

One of the key advantages of plastic molding for electrical components is its cost-effectiveness. The process enables manufacturers to produce large quantities of parts at a lower cost compared to other methods. This can result in significant savings for businesses while maintaining high quality standards.

Additionally, plastic molding offers design flexibility, allowing for intricate and complex shapes to be easily achieved. This versatility is essential in the electrical industry where components often require specific shapes and sizes to function optimally.

Enhanced Durability and Performance

Another benefit of plastic molding for electrical components is the enhanced durability it provides. The materials used in the molding process are selected for their strength and resistance to various environmental factors. This ensures that the produced components can withstand harsh conditions and continue to perform reliably over time.

Efficient Production and Assembly

Plastic molding for electrical components also streamlines the production and assembly processes. With the ability to create parts with tight tolerances and consistent quality, manufacturers can ensure that all components fit together seamlessly, reducing the risk of malfunctions and errors in the final products.

Applications of Plastic Molding in the Electrical Industry

The use of plastic molding for electrical components is widespread across a range of applications. From connectors and housings to insulators and switches, this process plays a critical role in the production of various electrical parts that are essential in modern devices and equipment.

Choose Deep Mould for Your Plastic Molding Needs

When it comes to plastic molding for electrical components, Deep Mould stands out as a trusted partner for businesses in need of reliable and high-quality solutions. With expertise in Metal Fabrication and a dedication to excellence, Deep Mould offers innovative molding services that meet the unique requirements of each client.

By leveraging the latest technologies and industry best practices, Deep Mould ensures that every component produced through plastic molding meets the highest standards of quality and performance. Partner with Deep Mould for your plastic molding for electrical needs and experience the difference in precision and efficiency.